- #Iso cleanliness standards Patch#

- #Iso cleanliness standards portable#

- #Iso cleanliness standards code#

We offer a variety of filtration equipment for every application from Dedicated Filter Panels to Portable Filter Carts.

Once you have determined your current Oil Quality, it is time to implement a filtration system to will best fit your needs. If interested, please contact regarding our Oil Analysis Bottle Sample Program. You can also take a bottle sample and send it out for analysis. This oil analysis test kit is a great complement to the on-line particle counter as it provides the capability to visually analyze oil contamination levels and types in the system.

#Iso cleanliness standards Patch#

Check out our PODs units for more information.Īnother option, is to utilize an Oil Analysis Patch Test Kit.

#Iso cleanliness standards code#

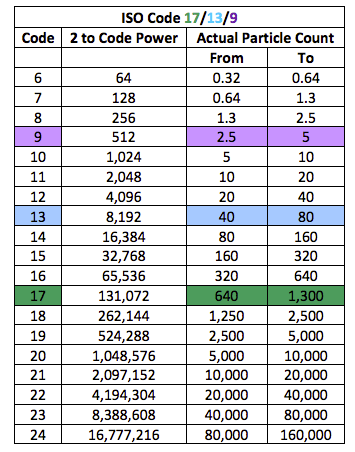

If a central reservoir supplies several systems, the overall cleanliness must be maintained, or the most sensitive component must be protected by filtration that cleans the fluid to the target before reaching that component.īest Practices to Achieve Your Target ISO Cleanliness Code Step 1: Perform an Oil Analysisĭirectly connecting an on-line particle counter, such as this Portable Oil Diagnostic System (PODS), to the hydraulic fluid or lube oil system through sampling ports provides the most accurate snapshot of oil cleanliness and eliminates many of the inherent variables associated with bottle sampling. The first step in identifying a target ISO code for a system is to identify the most sensitive component on an individual system, or the most sensitive component supplied by a central reservoir. Once you set a target ISO cleanliness code you should follow a progression of steps to achieve the target, monitor it, and maintain it, which will provide you with many justifiable rewards. Maximizing equipment reliability and safety, minimizing repair and replacement costs, extending useful fluid life, satisfying warranty requirements, and minimizing production down-time are attainable goals. When setting target ISO fluid cleanliness codes for hydraulic and lubrication systems it is important to keep in mind the objectives to be achieved. It is important to note that each time a code increases the quantity range of particles doubles. The code includes all particles of the specified size and larger. Each number represents a contaminant level code for the correlating particle size. This ISO code is expressed in 3 numbers: 19/17/14. The International Organization for Standardization created the cleanliness code 4406:1999 to quantify particulate contamination levels per milliliter of fluid at three sizes: 4µ, 6µ, and 14µ.

0 kommentar(er)

0 kommentar(er)